ST SDK5.0電機正反轉及轉速控制

阿新 • • 發佈:2018-12-11

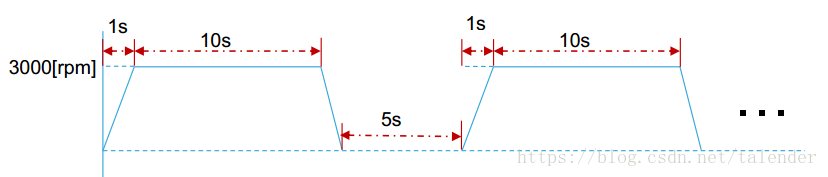

一、轉速控制

實現如圖控制:

while (1) { /* USER CODE END WHILE */ /* USER CODE BEGIN 3 */ MC_ProgramSpeedRampMotor1(3000/6,1000); //設定轉速為3000 MC_StartMotor1(); //馬達運轉 HAL_Delay(10000); //延時10S MC_ProgramSpeedRampMotor1(5000/6,1000); //設定轉速為5000 HAL_Delay(10000); MC_ProgramSpeedRampMotor1(2000/6,1000); //設定轉速為2000 HAL_Delay(10000); MC_StopMotor1(); //馬達停轉 HAL_Delay(5000); //延時5S } /* USER CODE END 3 */

通俗易懂,不做過多解釋

二、正反轉控制

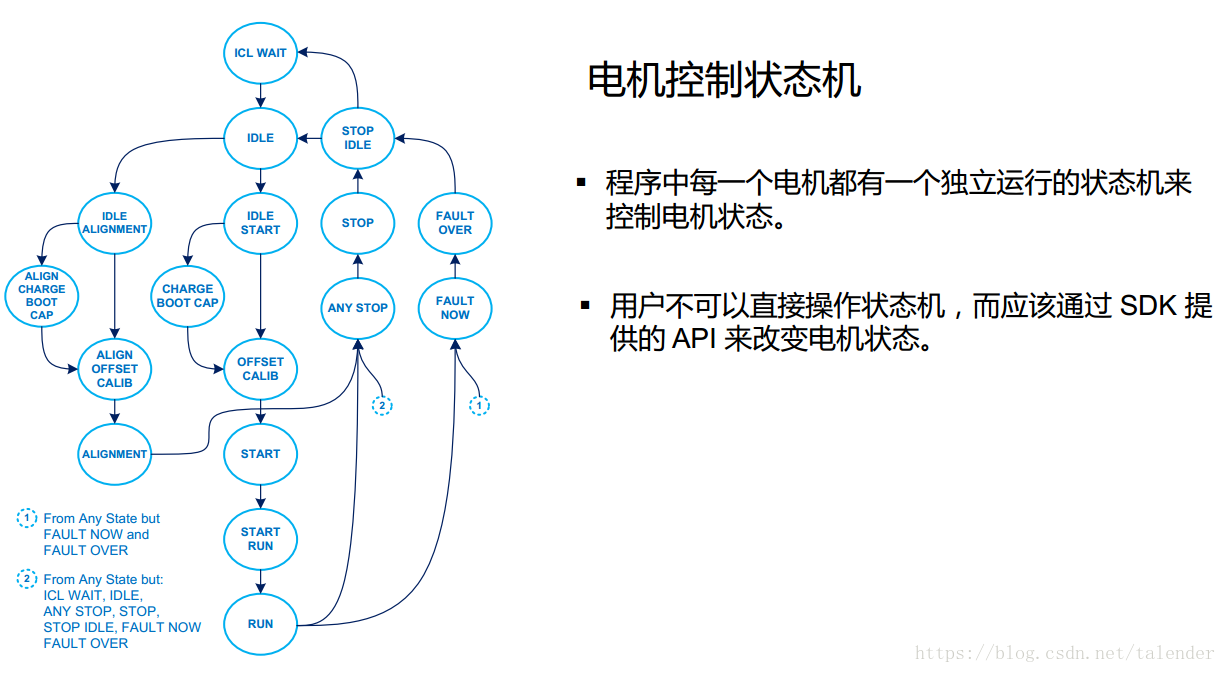

正反轉控制會遇到圖中的報錯問題,應先清除再重新啟動,手動workbench的道理相同。

1、新增標頭檔案

如果不新增這三個標頭檔案,在使用State_t等定義的型別時會報錯

#include "state_machine.h"

#include "mc_type.h"

#include "mc_tasks.h"2、 電機的狀態

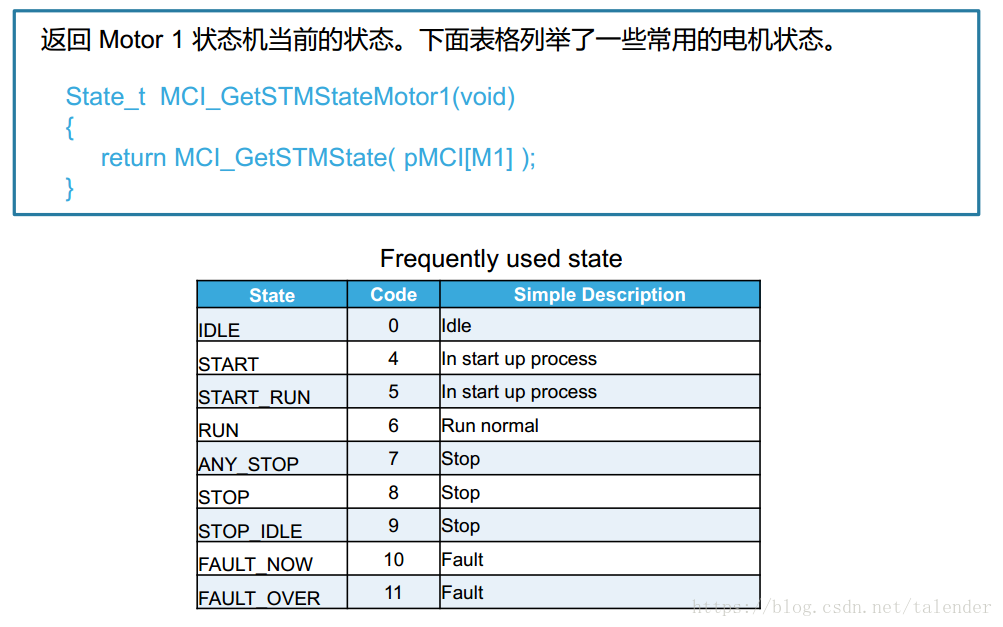

在ST的設定中電機有以上狀態,可在單步除錯時設定全域性變數,呼叫API觀測電機狀態

int cr=1;

ste = MCI_GetSTMStateMotor1();API解釋如下

說明:State_t為一列舉型別

typedef enum { ICLWAIT = 12, /*!< Persistent state, the system is waiting for ICL deactivation. Is not possible to run the motor if ICL is active. Until the ICL is active the state is forced to ICLWAIT, when ICL become inactive the state is moved to IDLE */ IDLE = 0, /*!< Persistent state, following state can be IDLE_START if a start motor command has been given or IDLE_ALIGNMENT if a start alignment command has been given */ IDLE_ALIGNMENT = 1, /*!< "Pass-through" state containg the code to be executed only once after encoder alignment command. Next states can be ALIGN_CHARGE_BOOT_CAP or ALIGN_OFFSET_CALIB according the configuration. It can also be ANY_STOP if a stop motor command has been given. */ ALIGN_CHARGE_BOOT_CAP = 13,/*!< Persistent state where the gate driver boot capacitors will be charged. Next states will be ALIGN_OFFSET_CALIB. It can also be ANY_STOP if a stop motor command has been given. */ ALIGN_OFFSET_CALIB = 14,/*!< Persistent state where the offset of motor currents measurements will be calibrated. Next state will be ALIGN_CLEAR. It can also be ANY_STOP if a stop motor command has been given. */ ALIGN_CLEAR = 15, /*!< "Pass-through" state in which object is cleared and set for the startup. Next state will be ALIGNMENT. It can also be ANY_STOP if a stop motor command has been given. */ ALIGNMENT = 2, /*!< Persistent state in which the encoder are properly aligned to set mechanical angle, following state can only be ANY_STOP */ IDLE_START = 3, /*!< "Pass-through" state containg the code to be executed only once after start motor command. Next states can be CHARGE_BOOT_CAP or OFFSET_CALIB according the configuration. It can also be ANY_STOP if a stop motor command has been given. */ CHARGE_BOOT_CAP = 16, /*!< Persistent state where the gate driver boot capacitors will be charged. Next states will be OFFSET_CALIB. It can also be ANY_STOP if a stop motor command has been given. */ OFFSET_CALIB = 17, /*!< Persistent state where the offset of motor currents measurements will be calibrated. Next state will be CLEAR. It can also be ANY_STOP if a stop motor command has been given. */ CLEAR = 18, /*!< "Pass-through" state in which object is cleared and set for the startup. Next state will be START. It can also be ANY_STOP if a stop motor command has been given. */ START = 4, /*!< Persistent state where the motor start-up is intended to be executed. The following state is normally START_RUN as soon as first validated speed is detected. Another possible following state is ANY_STOP if a stop motor command has been executed */ START_RUN = 5, /*!< "Pass-through" state, the code to be executed only once between START and RUN states it’s intended to be here executed. Following state is normally RUN but it can also be ANY_STOP if a stop motor command has been given */ RUN = 6, /*!< Persistent state with running motor. The following state is normally ANY_STOP when a stop motor command has been executed */ ANY_STOP = 7, /*!< "Pass-through" state, the code to be executed only once between any state and STOP it’s intended to be here executed. Following state is normally STOP */ STOP = 8, /*!< Persistent state. Following state is normally STOP_IDLE as soon as conditions for moving state machine are detected */ STOP_IDLE = 9, /*!< "Pass-through" state, the code to be executed only once between STOP and IDLE it’s intended to be here executed. Following state is normally IDLE */ FAULT_NOW = 10, /*!< Persistent state, the state machine can be moved from any condition directly to this state by STM_FaultProcessing method. This method also manage the passage to the only allowed following state that is FAULT_OVER */ FAULT_OVER = 11 /*!< Persistent state where the application is intended to stay when the fault conditions disappeared. Following state is normally STOP_IDLE, state machine is moved as soon as the user has acknowledged the fault condition. */ } State_t;

3、正反轉控制

在文件範例上有其他控制方法,以下為自己思考,對電機狀態理解有好處

while(1)

{

//======第一圈

if(cr) //cr為while外一整型,用來湊第一圈

{

MC_StartMotor1();

MC_ProgramSpeedRampMotor1(1000/6,1000);

HAL_Delay(10000);

cr=cr-1;

}

//====其他圈

else

{

//MC_StartMotor1();

MC_ProgramSpeedRampMotor1(1000/6,1000);

HAL_Delay(5000); //反轉速度後必須延時,留一個報錯的時間

ste = MCI_GetSTMStateMotor1();

if(ste==11||ste==10) //如果狀態為Fault

{

MC_AcknowledgeFaultMotor1(); //清除報錯

MC_StartMotor1();

HAL_Delay(5000); //啟動延時,啟動是一個過程

int16_t lastspeed=MC_GetLastRampFinalSpeedMotor1();

MC_ProgramSpeedRampMotor1(1000/6, 1000);

MC_StartMotor1();

HAL_Delay(10000);

}

}

//=========反轉===========

//MC_StartMotor1();

MC_ProgramSpeedRampMotor1(-1000/6,1000);

HAL_Delay(5000); //反轉速度後必須延時,留一個報錯的時間

ste = MCI_GetSTMStateMotor1();

if(ste==11||ste==10)

{

MC_AcknowledgeFaultMotor1();

MC_StartMotor1();

HAL_Delay(5000);

int16_t lastspeed=MC_GetLastRampFinalSpeedMotor1();

MC_ProgramSpeedRampMotor1(-1000/6, 1000);

MC_StartMotor1();

HAL_Delay(10000);

}

else

{

HAL_Delay(10000);

}

}